A Comprehensive Guide to Centrifugal Pump

What is a Centrifugal Pump?

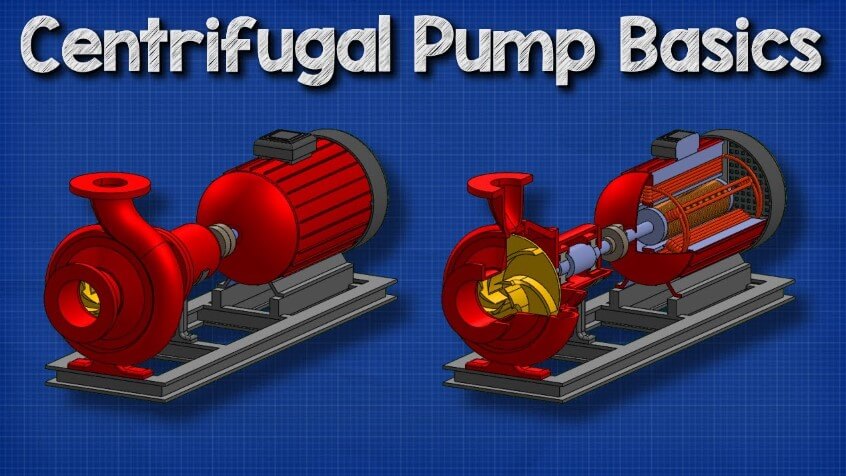

A Centrifugal Pump is a programmed framework comprised of two fundamental parts; a pump and an electrical engine. The critical part at the core of a centrifugal pump is the impeller which turns quickly on a pivot during activity granting centrifugal power onto the liquid empowering it to travel through the pump packaging and to the pull outlet. The impeller is made of profoundly consumption-safe cast iron highlighting bent vanes and cover plates. A centrifugal impeller will constantly require being completely lowered in water to empower preparation during activity except if the pump framework as of now has self-preparing capacities.

As a centrifugal pump utilizes a rotational impeller framework and works at a low/medium strain head, it contrasts with numerous different pump working standards which for the most part fall into the positive relocation pump class. These pump types normally move liquid with a diaphragm pump framework or responding plan.

What is a Pump Curve?

To choose a pump for a framework, engineers measure a pump’s presentation capacities by plotting a pump curve. Pump curves are graphical portrayals of a given pump that, once determined, gives the fundamental data for the presentation qualities and capacities that will be expected of that pump. Utilizing an x-y chart, on many occasions, the proportion of head strain will be addressed on the upward hub and the stream limit will be addressed on the even hub in GPM (gallons each moment). Remember, while survey pump stream diagrams, units are estimated as gallons and feet in the U.S. and liters and meters all through the remainder of the world.

The Most Effective Method to Read Curves of Pump

Find the most elevated mark of a pump bend on the left and note the line’s progressive bend down to the right. Moving left to right, the bend shows contrasting measures of stream and strain until the bend closes. Note the x-y points of convergence. Each crossing point on the bend shows the stream rate the pump produces at a specific degree of strain to accomplish an ideal level when the pump is inactivity. On the other hand, the strain the pump works at likewise exhibits a specific stream rate.

Torque (HP) necessities for pump applications are additionally addressed on pump bends. While perusing a bend, pull shows how much power the pump expects to work proficiently at a specific stream point. This guarantees the engine chosen is the right size for the application and is helpful to ascertain power utilization costs. Units to gauge strength are addressed in kilowatts.

How a Centrifugal Pump Works

Centrifugal pumps move liquid by utilizing diffusive power to create the speed of the fluid. The pull spout directs a liquid stream through the eye of the impeller, into the pump’s inner workings. The impeller vanes get the liquid and pivot it, both extraneously and centrifugally until it leaves the pump on the release side. As the liquid leaves the pump it’s under more prominent tension than when it entered. Is it true that the impeller now does all of the work? No, it’s just a piece of the pressure-driven plan of the centrifugal pump curve. The impeller is just helpful assuming the fluid being pumped is constrained by the volute. The volute is one more piece of the water-driven plan that changes the speed of the fluid into strain and controls the pumped fluid as it’s released from the pump.

Benefits of Using a Centrifugal Pump

-

Erosion Resistance

Walk Pumps centrifugal pumps have a demonstrated history concerning strength. The mystery lies in their capacity to endure elevated degrees of destructive fluids from different synthetic compounds. Synthetic wholesalers and makers as well as those dealing with profoundly destructive liquids can do many applications with next to no never-ending apprehension about soaring mileage costs. On account of the capability of expanded help existence with March Pump’s centrifugal pump’s unwavering quality, you stand to partake in an upgraded profit from the venture.

-

Energy Efficiency

In any modern arrangement that uses pumps, energy costs are reliably one of, on the off chance that not, the biggest components for pump frameworks. Regardless, patterns in enterprises appear to incline toward centrifugal pumps over other pump frameworks about energy reserve funds. Anything the applications being referred to are, ventures could surely profit from effective energy use, all the more so if the applications include a progression of different centrifugal pumps.

-

Smooth Flow

Another centrifugal pump benefit has to do with its stream. The impellers inside the pump move in a smooth turning movement that provisions an even strain all through the liquid. This, therefore, prompts a more uniform release of liquids contrasted with a positive uprooting pump’s throbbing and unpredictable movement. The drawback of having a lopsided and throbbing smooth movement is it powers architects to make unique plan contemplations in lines to forestall breaks and different types of shortcomings along the lines. This might cause plan, establishment, and functional expenses to the wind.

-

Demonstrated Reliability

There is a motivation behind why individuals continue to return to centrifugal pumps for long-haul liquid exchange applications. It is because they have a demonstrated history of unwavering quality. They will quite often have a rougher plan than responding pumps which improve their solidness. Walk Pump’s centrifugal pumps serve a large number of ventures and are inclined toward thanks to their withstanding execution.

-

Low Maintenance

Centrifugal pumps typically require less upkeep than positive dislodging pumps, although both have genuinely clear support schedules. In what manner or capacity? Centrifugal pumps have fewer moving parts than positive removal pumps, and that implies they frequently have a more extended presentation time. Furthermore, with fewer moving parts, fix times are probably going to be more limited and less expensive on the occasion an issue emerges.